Promo discount alert!🚨

.

With Christmas and New Year's coming up we’re reducing the price of our visco fuse machine plans (either version) by 20% until midnight on the 31st of December (GMT).

.

Simply use discount code “Festive20” at the checkout! Merry Christmas!

To make the lacquer you will need Acetone (a cleaning solvent available at most chemists), a glass jar with an airtight lid, scissors and ping pong balls.

Take a ping pong ball (this contains the nitrocellulose) and cut it into small pieces. Cutting the ball into small pieces increase the material’s surface area and speeds up the process of turning this solid into a liquid.

Place these pieces into a glass jar with a sealable airtight lid.

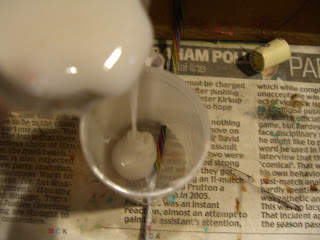

Pour Acetone into the jar so that it a little more than covers all of the pieces of plastic.

I then apply a small amount of lacquer to the end of my fuse which is still under tension in my Visco machine. Once dry, this allows me to cut the fuse at this point without the thread unravelling.

I then feed this fuse tip through a small opening in a “coating tank” – a rather grand name, for in my case this constitutes a photo film canister. The fuse tip is passed through a slightly larger opening in the other side.

The nitrocellulose lacquer is then poured into the tank and the fuse is drawn though it directly from the visco machine. This gives the first coat and binds the fuse together. The fuse is removed from the machine and a further coat or two is applied as necessary to ensure an even and unbroken coverage. The result is a durable fuse capable of withstanding manipulation; lift chargers, break charges and burning in wet conditions, or even underwater.

This comment has been removed by the author.

ReplyDeleteCan it be made with solvent instead of with acetone?

ReplyDeleteHi, thanks for your comment. The cellulose is in the ping pong balls, so as long as you have a solvent capable of dissolving the ball into a smooth liquid, which will then evaporate to leave the plasticized cellulose hard again then this should work. Acetone in readily available though, either neat or as a high percentage in nail polish remover.

Delete